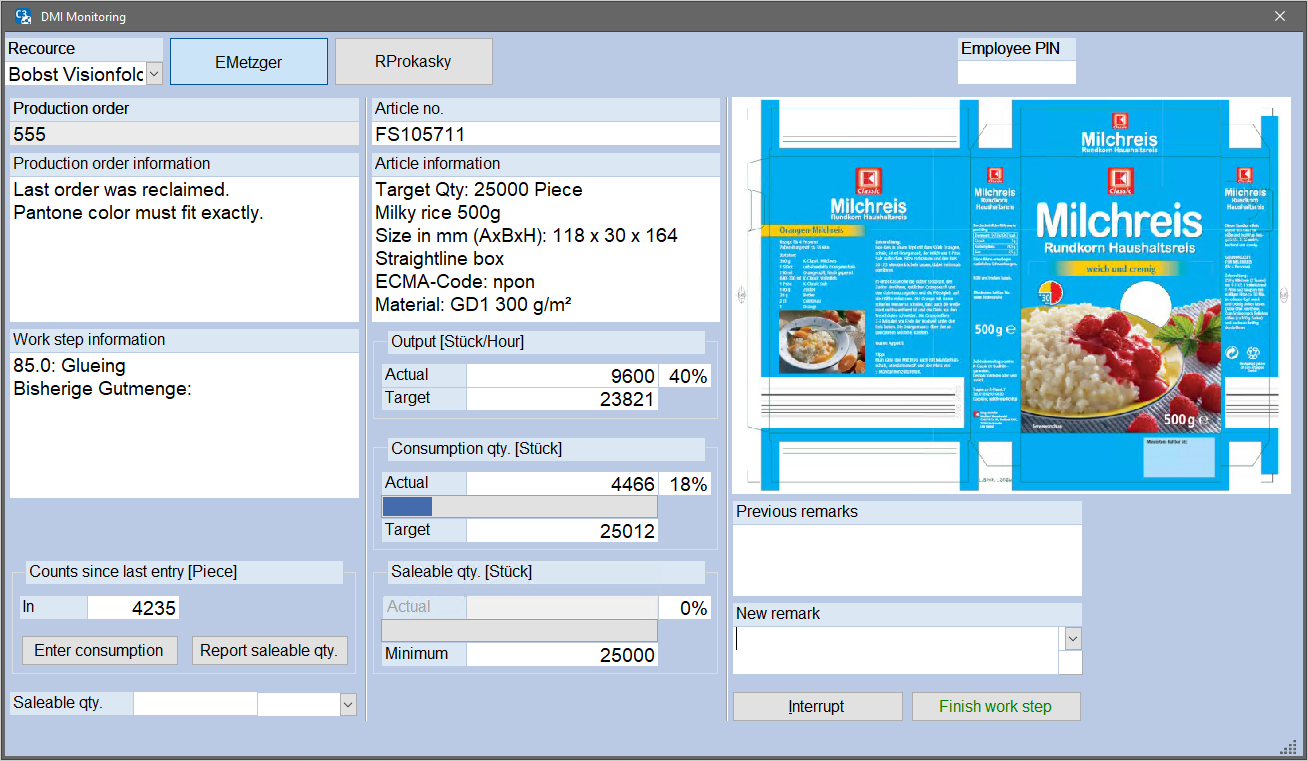

Shop floor data collection to production order and articles

The production data can be registered in normal PC jobs, mobile equipment or daily notices. tacks produces special barcodes for articles and products, making the recording of usage of stock and materials made easy and error proof for your production employees. In addition, a project time registration is integrated through which dates and times can be recorded and analyzed later on certain orders, quotations, projects or customers. Recording of working times for your employees (start/ break/ finish) are available for cost and pay slip administration.

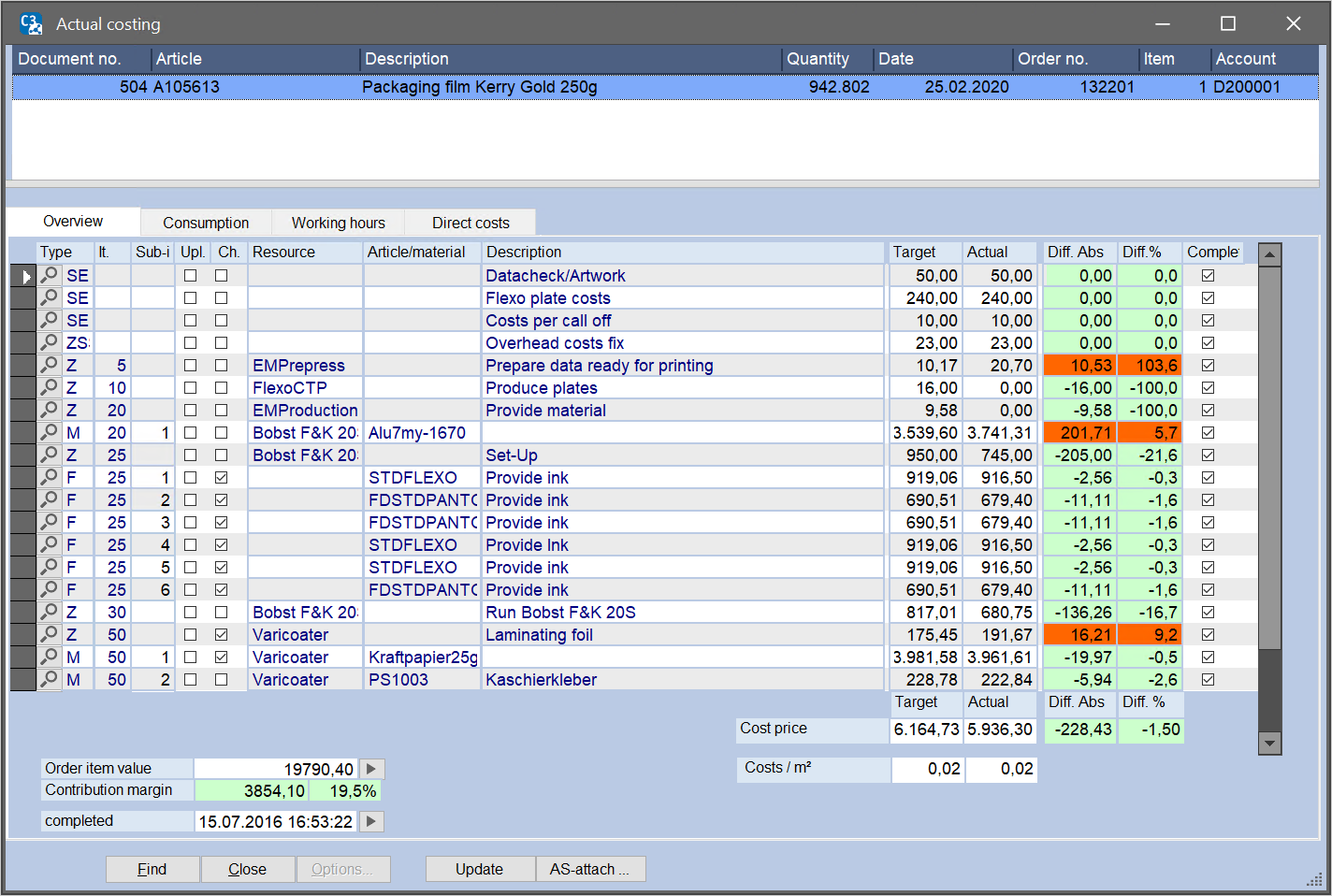

Accounting with time overview of the SFC

The evaluation of the recorded material withdrawals and processing times leads to the establishment of “green” and “red” areas, which are directly compared with the preliminary costing. This lets you see at a glance whether the order was processed at a profit, where problems emerged or if the assumptions made during costing were incorrect. Detailed evaluations on divisional, resource or material levels allow non-profitable production steps to be identified.