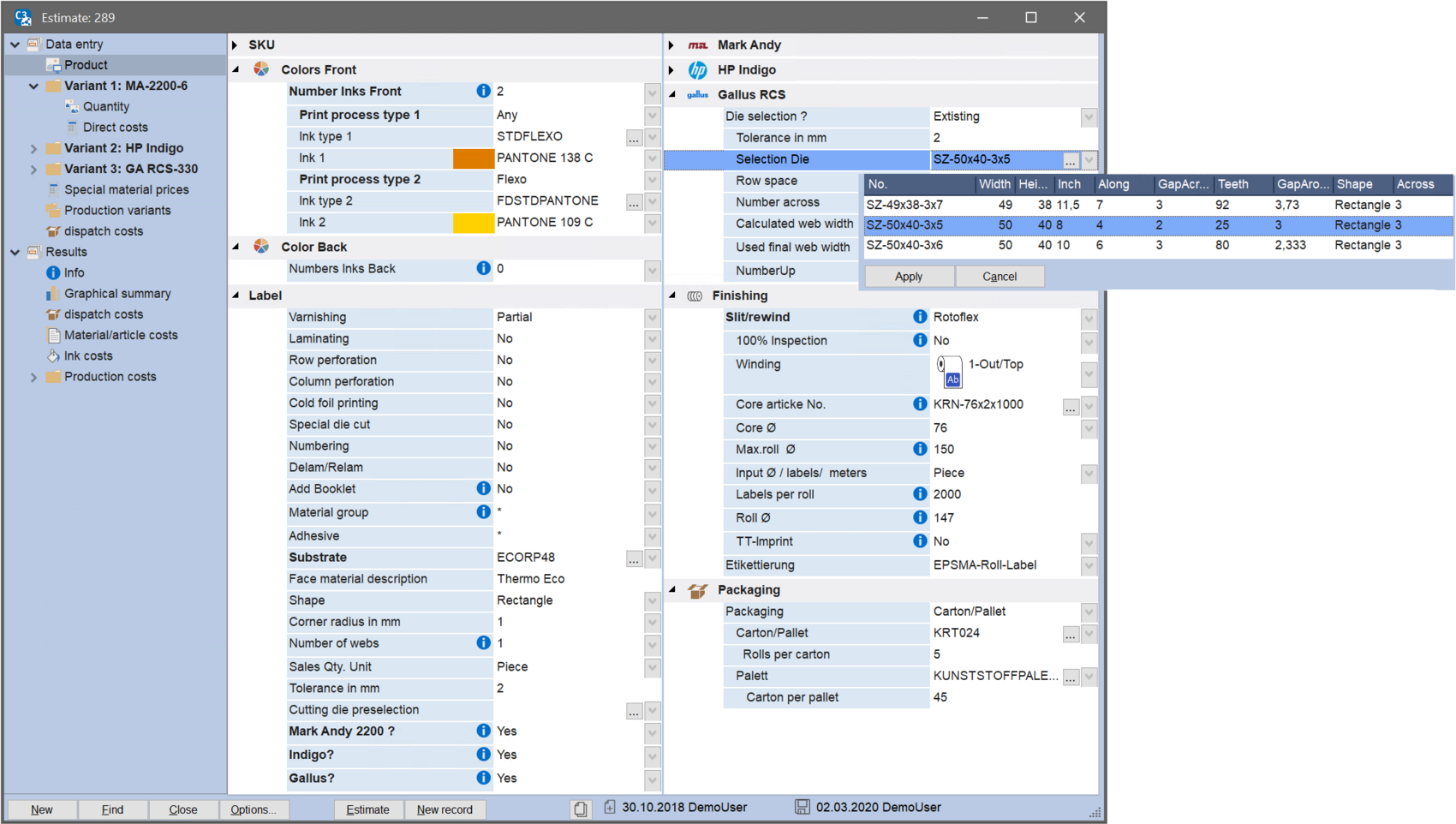

Simultaneous estimate of different productions variants including all details

With support of the shop floor control system [SFC] estimated costs and actual cost can be easily compared automatically for all production orders. Due to this automated comparison, differences between estimated and actual costs are already discovered during the production process.

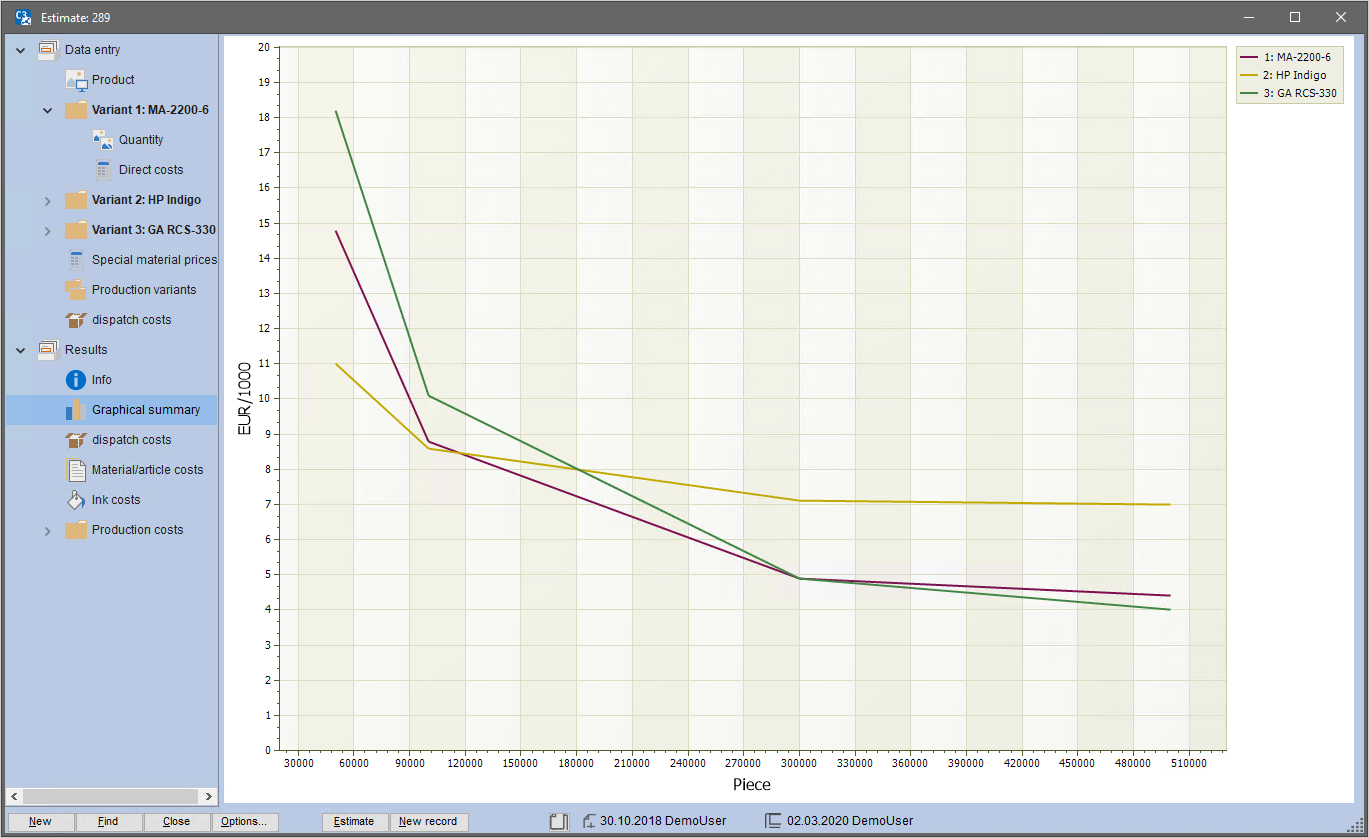

Graphical representation of the unit cost

The built-in production-versions calculation allows multiple production versions, e.g. for different criteria, to be calculated and compared at the same time. Here, tacks simulates complete production e.g. in a digital roll and conventional sheet production to determine the optimal production method for each required quantity.

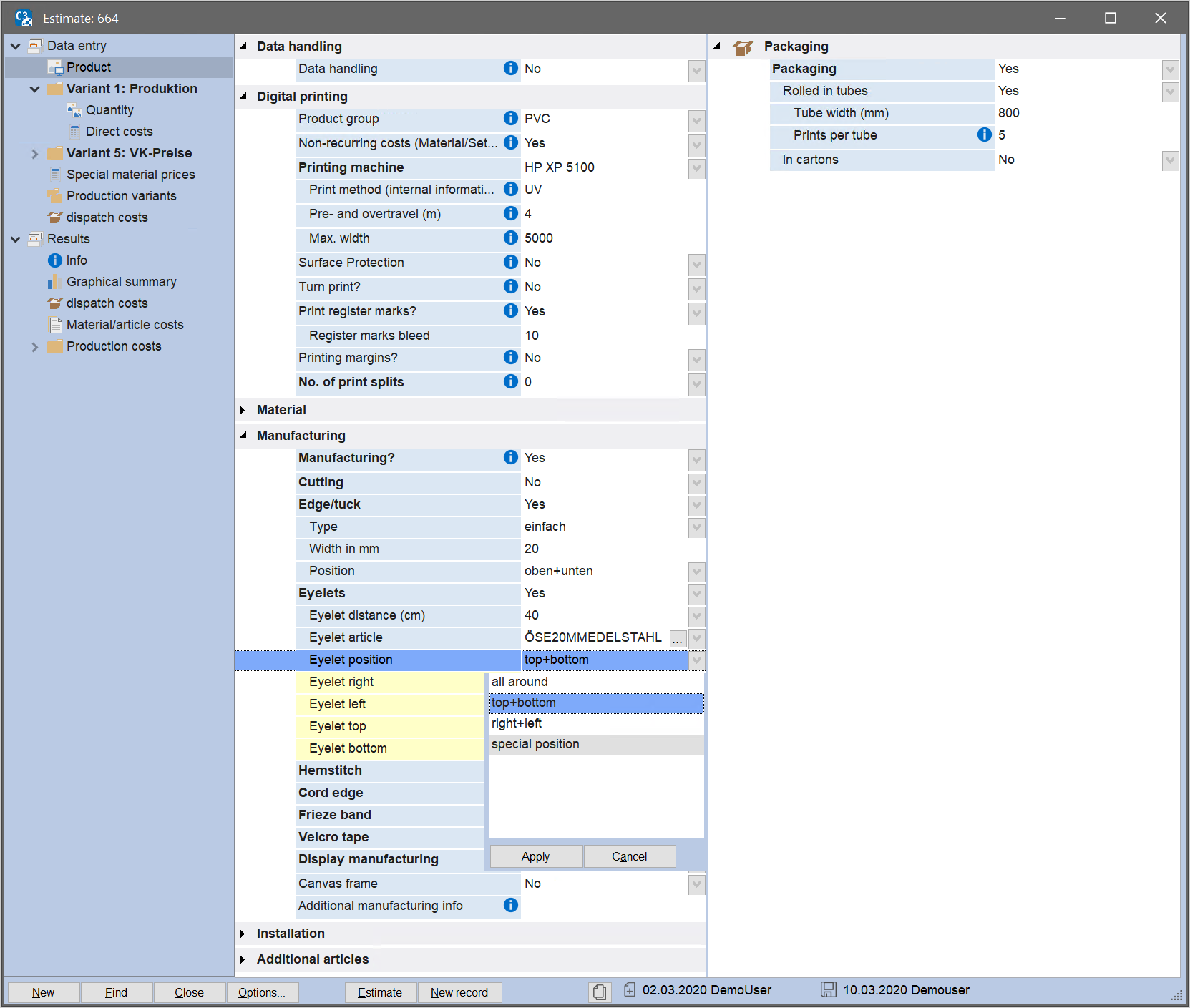

Every estimate becomes even simpler and faster with the fully integrated product configurator. Moreover, costs can no longer be overlooked. All data which is dependent for an estimate of a certain product is verified by tacks. In the background tacks turns this into the complete working plan and calculates the estimate according to your company specific rules. Moreover, all required data for a later actual cost comparison is already calculated. You can set rules and restriction conditions for certain characteristics of the product class for every product. Your own rules are customized, but not hard-coded, so they don’t need to be changed for a software update.

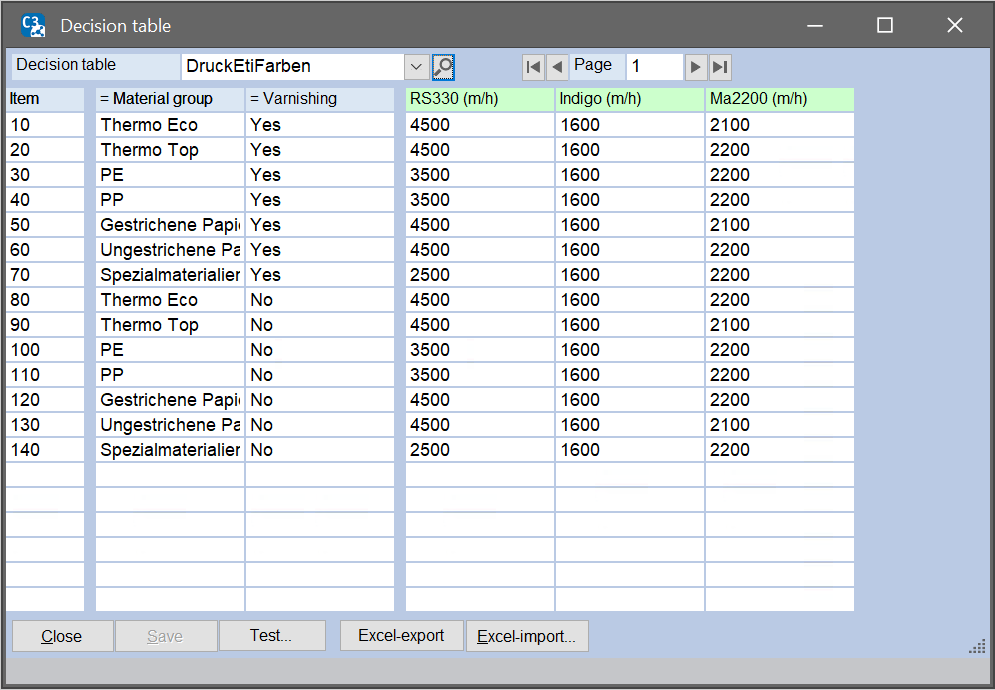

Complex rules and plausibility examinations during estimating are simplified by decision tables. Resulting values could be the make ready time and the press speed for each combination of criteria. Decision tables you create ensure that every employee works with the same criteria and receive the same estimated prices for every product.